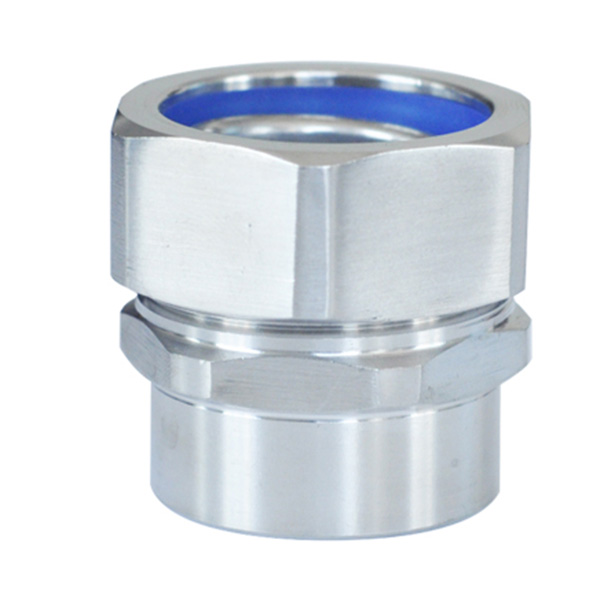

Explosion-proof Mini Bushing

Explosion-proof Mini Bushing

Explosion-proof mini conduit box is a type of explosion-proof equipment used

in external hazardous environments. The explosion-proof conduit box is

cast from aluminum alloy and has a surface that is spray-coated,

providing strong corrosion resistance to achieve the corresponding

explosion-proof rating. It is primarily used for the transition and

sealing protection of conduit routes between conduits and between walls

and conduits in corrosive environments. It has high impact resistance

and corrosion resistance, making it suitable for environments prone to

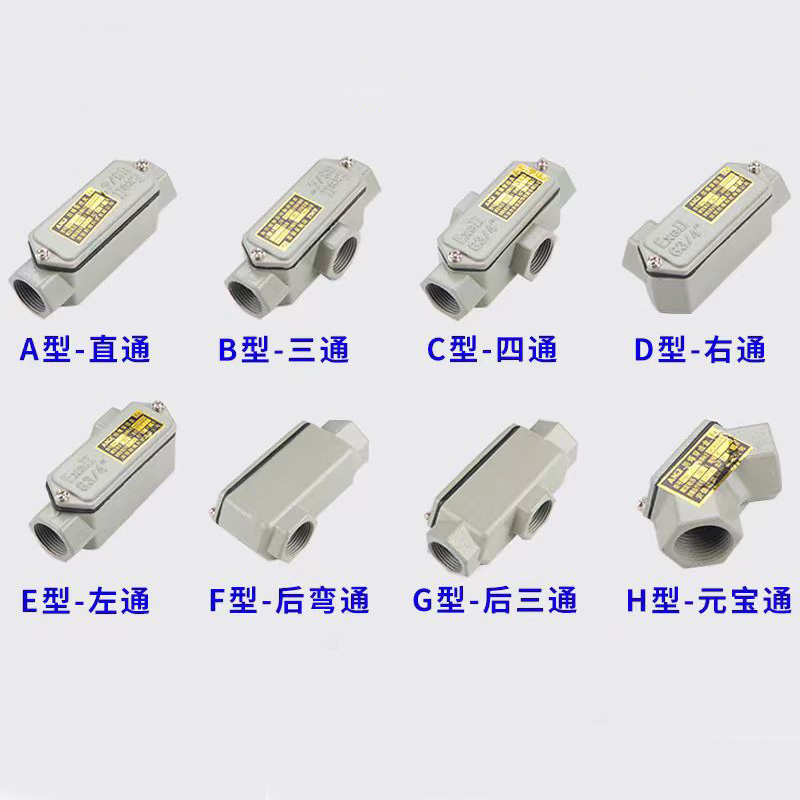

corrosion. The explosion-proof conduit box comes in various structural

forms to meet different wiring needs on-site, typically made of cast

steel or cast aluminum alloy, offering good performance in corrosion

resistance, oxidation resistance, antistatic properties, and resistance

to sunlight exposure.

Quotation

Execution

Ex eb C T6 Gb/Ex tb mC T80℃ Db

IP Grade

IP66 lP65

Rated voltage

380V

Thread specifications

G(PF) threads

-Widely used for lighting, power, and control circuit connections in hazardous environments such as oil exploration, refining, chemical industry, and military industries.

-Suitable for Zone 1 and Zone 2 explosive gas environments.

-Suitable for Zone 21 and Zone 22 combustible dust environments.

-Suitable for explosive gas environments of Class IA, IIB, and IC.

-Suitable for temperature groups T1-T6.

-Standards: GB/T3836.1, GB/T 3836.2, GB/T3836.3, GB/T3836.31, IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-31, EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-31.

Product Features:

-Made of cast aluminum alloy or cast steel (only Class II C) with a surface coated with high-pressure electrostatic spraying.

-Various ways and specifications for cable entry and exit.

-Suitable for conduit wiring (please specify for cable wiring).

Explosion-proof conduit boxes are a type of explosion-proof device used in hazardous environments. They are made of cast aluminum alloy, and the surface of the explosion-proof conduit boxes is coated through spraying, providing strong corrosion resistance and achieving the corresponding explosion-proof rating. These boxes are mainly used for the transition and sealing protection of conduit wiring between conduit pipes and walls, offering strong impact resistance and corrosion resistance, suitable for corrosive work environments. The structure of explosion-proof conduit boxes is diverse, meeting various on-site wiring needs, and they are typically made of cast steel or cast aluminum alloy, with good performance in terms of anti-corrosion, oxidation resistance, antistatic properties, and resistance to sunlight exposure.