Explosion-proof Mini Junction Boxes

Explosion-proof Mini Junction Boxes

Explosion-proof mini junction boxes are used in hazardous areas, primarily

within buildings and structural frameworks, as well as for cable

direction changes. Cable conduit connections are made with

explosion-proof junction boxes, while conduit-to-ground connections use

flexible hoses. Metal hoses or flexible connections are applied as

protective tubing when the explosion-proof junction box is connected to

the local surface of thermocouples, resistance thermometers,

transmitters, etc. Elbows are commonly used at bends in explosion-proof

junction boxes. An explosion-proof junction box should be installed when

there are more than two 90° elbows or the straight conduit length

exceeds 30m.

Quotation

Execution

Ex eb C T6 Gb/Ex tb mC T80℃ Db

IP Grade

IP66 lP65

Rated voltage

380V

Rated current

20A

-Widely used in hazardous environments such as oil exploration, refining, chemical industry, and military industries for the connection of lighting, power, and control circuits.

-Suitable for Zone 1 and Zone 2 explosive gas environments.

-Suitable for Zone 21 and Zone 22 combustible dust environments.

-Suitable for explosive gas environments of IA, IIB, and IC classes.

-Suitable for temperature groups T1-T6.

-Compliance with standards: GB/T3836.1, GB/T 3836.2, GB/T3836.3, GB/T3836.31, IEC 60079-0, IEC6O079-1, IEC 60079-7, IEC 60079-31, EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-31.

-Thread specifications: G1/2", G3/4", G1", G11/4", G2", NPT1/2", NPT3/4", NPT1", NPT11/4", NPT112”, NPT2", M20×1.5, M25×1.5, M32×1.5, M40×1.5, M50×1.5, M63×1.5.

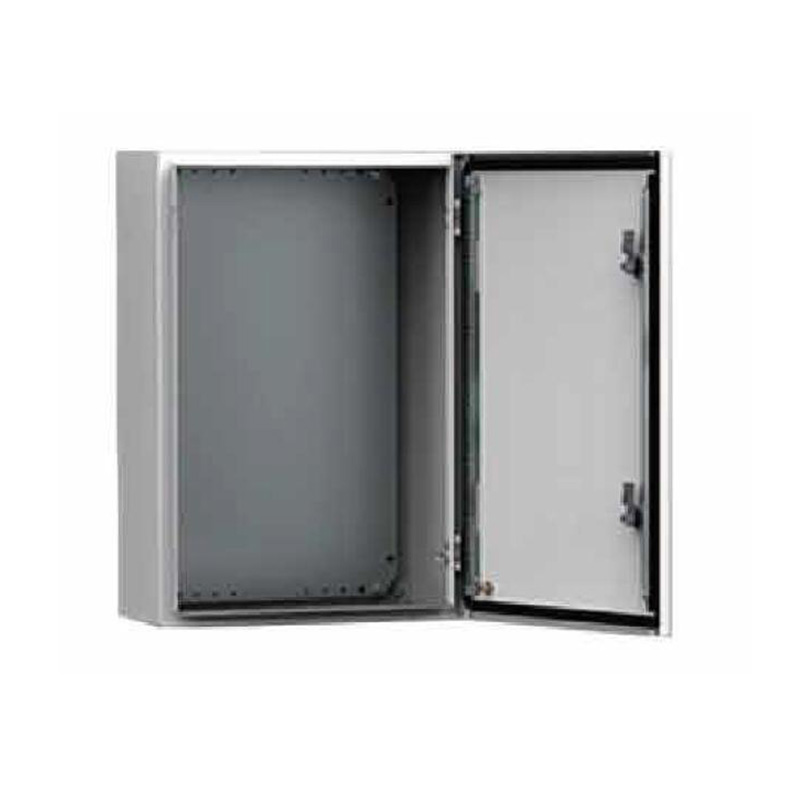

Product Features:

-Cast aluminum alloy or cast steel (only for IIC) housing with high-voltage electrostatic spraying on the surface.

-Various methods and specifications for inlet and outlet ports.

-Stainless steel exposed fasteners.

-Customizable thread forms for inlet and outlet ports, such as metric threads and NPT threads.

-Suitable for steel pipe wiring (please specify for cable wiring).

-Explosion-proof lighting fixtures can be directly suspended through steel pipe wiring using junction boxes with lifting covers.

Explosion-proof junction boxes are used in hazardous areas, primarily within buildings and structural frameworks, as well as for cable direction changes. Cable conduit connections are made with explosion-proof junction boxes, while conduit-to-ground connections use flexible hoses. Metal hoses or flexible connections are applied as protective tubing when the explosion-proof junction box is connected to the local surface of thermocouples, resistance thermometers, transmitters, etc. Elbows are commonly used at bends in explosion-proof junction boxes. An explosion-proof junction box should be installed when there are more than two 90° elbows or the straight conduit length exceeds 30m.